78711-R,20

78710-R,10

78712-R,50

orGN 300-30-B5-SW;60

GN 612-5-M12x1,5-A;40

DIN 172-B10,5-20-A;50

ISO 8675-M8x1-04-BT;10

Types

Lever

Steel

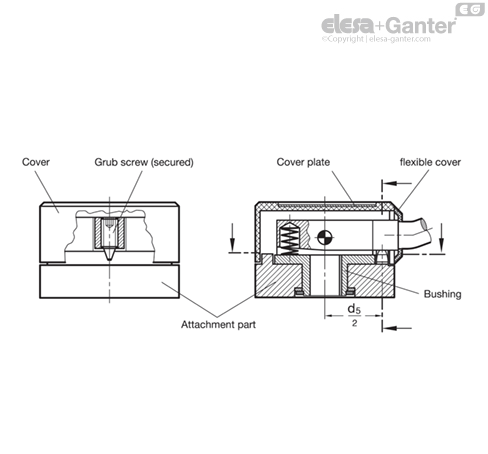

Cover

Plastic

Ball knob DIN 319

Plastic, phenolic resin (PF)

Black, shiny finish

With indexing levers GN 215 shafts can be turned through a predetermined angle and positively locked. To index, lift the lever against spring pressure from serrations (one hand control).

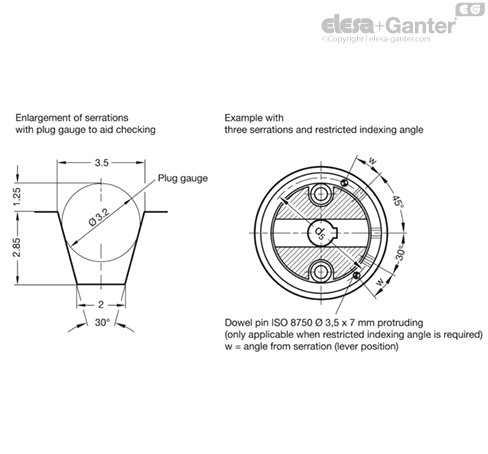

Limiting the indexing angle can be achieved with two dowels (sketch).

The bushing is connected to the shaft via keyway.

The location flange is bolted to the machine with two socket head cap screws (M 5).

The lever, via the location pin, provides the connection between shaft and location flange.

The serrations are protected from swarf and similar particles by the cover. This cover can be inserted by hand (elastic segments engage into a groove) and removed with a screw driver.

The location pin is a wedge-type as standard, which guarantees backlash-free positioning and also achieving easy engagement and disengagement.

If backlash-free positioning is not required, a dowel pin (made from a grub screw DIN 915-M6x14) can be used. The serrations can be made square or with dowels and suitable holes. Such holes have to be made large enough to ensure that the dowel is not restricted on engagement (lever swivel radius).

Smallest available angle for special serrations:

11º for size 54

9º for size 60

Smaller angles can be acheived with suitable serrations and dowels.

Your request was sent and will be answered as fast as possible.