CFM-TR-G

78711-R,20

78710-R,10

78712-R,50

orGN 300-30-B5-SW;60

GN 612-5-M12x1,5-A;40

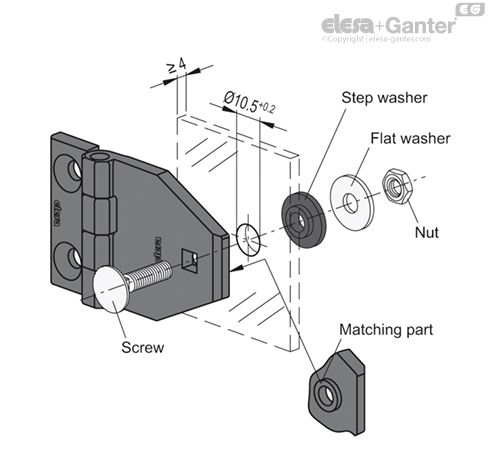

DIN 172-B10,5-20-A;50

ISO 8675-M8x1-04-BT;10

Glass-fibre reinforced polyamide based (PA) SUPER-technopolymer, black colour, matte finish.

A4 UNI 6593-MT stainless steel.

NBR rubber, hardness 70 Shore A.

Produced from FDA compliant raw material (FDA CFR.21 and EU 10/2011).

AISI 303 stainless steel.

Frame side: pass-through holes for countersunk head screws.

Panel side: pass-through hole for round head square neck bolts according to UNI 5732 (choose the correct screw length depending on the thickness of the glass or of the panel).

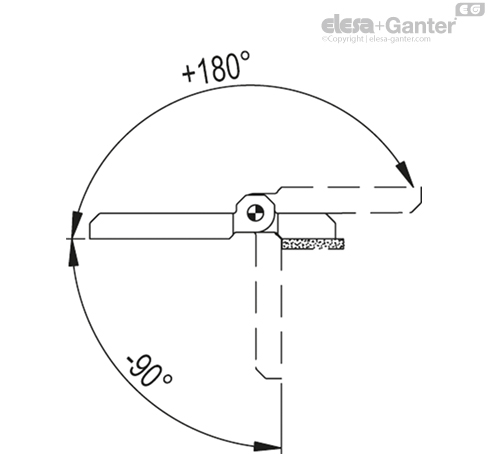

Max 270° (-90° and +180° being 0° the condition where the two interconnected surfaces are on the same plane).

Do not exceed the rotation angle limit so as not to prejudice the hinge mechanical performance.

To choose the convenient type and the right number of hinges for your application, see the Guidelines.

| Resistance tests | AXIAL STRESS | RADIAL STRESS | 90° ANGLED STRESS | |||

| Description | Maximum working load Ea [N] | Load at breakage Ra [N] | Maximum working load Er [N] | Load at breakage Rr [N] | Maximum working load E90 [N] | Load at breakage R90 [N] |

| CFM-TR-G-B.40-SH-5 | 300 | 750 | 420 | 2500 | 420 | 1000 |

| CFM-TR-G-B.50-SH-6 | 270 | 1040 | 480 | 3500 | 480 | 1000 |

| CFM-TR-G-B.60-SH-6 | 250 | 1200 | 370 | 5000 | 370 | 2500 |

The maximum operating load values of the different hinges shown in the tables are merely indicative. They are the result of tests carried out in our laboratories at controlled temperature and humidity (23°C - 50% RH), under specific conditions of use and for a limited period of time. In any case, it is advisable to verify correct operation during installation of the structure.

At least two hinges need to be mounted for correct operation.

Your request was sent and will be answered as fast as possible.