GN 5861

78711-R,20

78710-R,10

78712-R,50

orGN 300-30-B5-SW;60

GN 612-5-M12x1,5-A;40

DIN 172-B10,5-20-A;50

ISO 8675-M8x1-04-BT;10

Type

Eye ring

Steel 1.6541

Bearing case

Steel 1.6541

Weld-on flange

Steel 1.6541

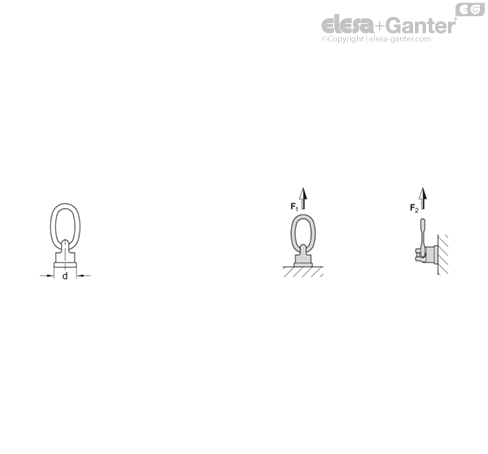

Load rings GN 5861 rotate by means of a ball bearing and are used with separate lifting gear and lashing equipment. They are welded to load-bearing equipment or directly onto the load itself and absorb loads in any direction. The large ring facilitates attachment.

The nominal load capacity is indicated on the ring. Load rings GN 5861 comply with the Machinery Directive 2006/42/EC and DGUV rules GS-HM-36.

| Diameter d | Nominal load capacity | F1 | F2 |

| in t (WLL) | max. in t | max. in t | |

| 40 | 0.63 | 0.63 | 0.63 |

| 46 | 1.5 | 1.5 | 1.5 |

| 61 | 2.5 | 2.5 | 2.5 |

| 78 | 4 | 4 | 4 |

| 95 | 5 | 6.7 | 5 |

| 100 | 8 | 10 | 8 |

The specified load values apply to an operating temperature range of –40 °C to +200 °C. Further information can be found in the operating instructions.

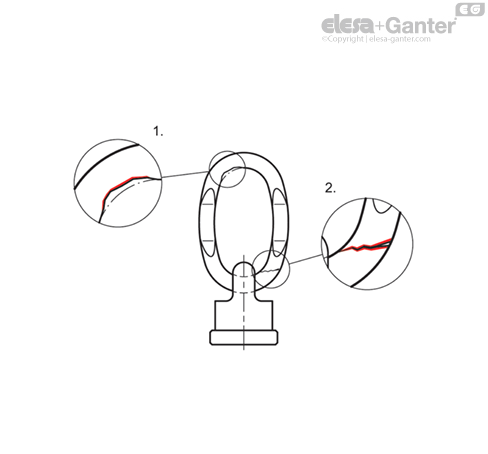

1. If the wear exceeds 10% of the cross-section, the lifting point is worn out and has reached the end of its service life.

2. If the load ring is bent or shows signs of damage or cracks, it is no longer safe to use.

In either case, replacement is required.

The information in the operating instructions must be complied with during installation, commissioning and use. It is included with the product and is available digitally at elesa-ganter.com.

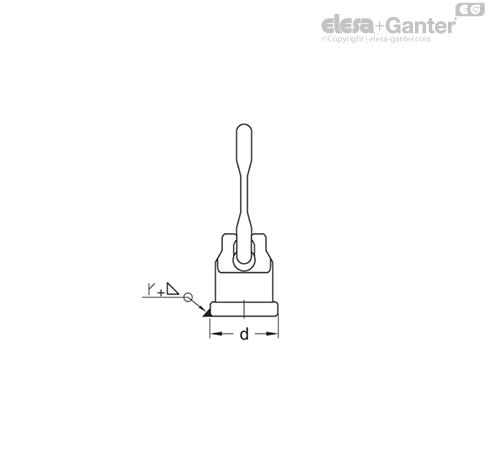

| Diameter d | Size of weld seam |

| 40 | a4 |

| 46 | a5 |

| 61 | HY 3 + a5 |

| 78 | HY 3 + a6 |

| 95 | HY 3 + a8 |

| 100 | HY 3 + a10 |

The welding must be carried out by a certified welder in accordance with ISO 9606-1.

Your request was sent and will be answered as fast as possible.