SFP-EX

78711-R,20

78710-R,10

78712-R,50

orGN 300-30-B5-SW;60

GN 612-5-M12x1,5-A;40

DIN 172-B10,5-20-A;50

ISO 8675-M8x1-04-BT;10

Polyamide based (PA) technopolymer.

NBR synthetic rubber.

Technopolymer.

SFP-EX breather caps comply with the Essential Health and Safety Requirements of the European ATEX Directive 2014/34/ EU (explosive atmospheres) for Group II devices, category 2GD.

II 2GD Ex h X: is the breather caps identification marked on the SFP-EX product according to ATEX directive

II: group of devices / components suitable for use in surface industry except for mines.

2: ATEX category corresponding to "high" protection level

G: explosive atmosphere of flammable gases or vapors.

D: explosive atmosphere of combustible dusts.

Ex: device / component protected against the ignition of explosive atmospheres.

h: protection mode for non-electric devices / components.

X: special conditions and limitation of use (see Instructions for use).

Ambient and/or fluid temperature: -20 ÷ +80 °C

The documentation concerning the conformity of this product to the European Directives above mentioned and the instructions for use are integral parts of the article itself.

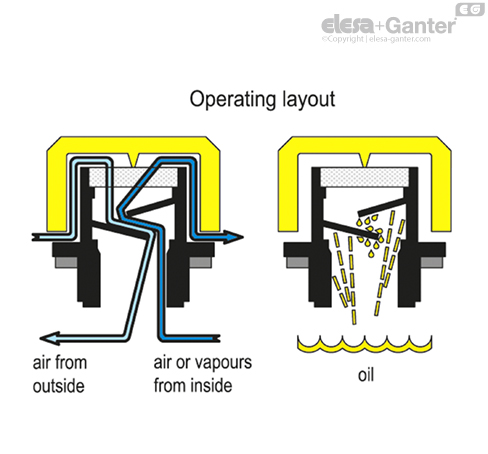

SFP-EX breather caps come complete with splash guard device (ELESA original design) that prevents oil loss and are particularly suitable for use where oil is violently agitated and could be splashed against breather cap. The correct positioning of the article in the design phase is essential to prevent accidental spills of liquid. In particularly heavy use conditions or very dusty environments the filters could progressively deteriorate, compromising the correct functioning of the article. Proper periodic maintenance is recommended.

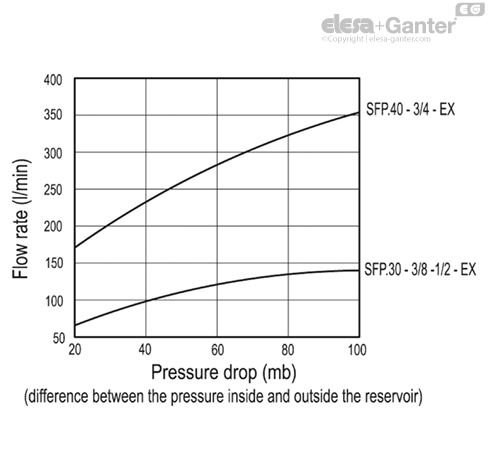

Air flow rate for each model can be determined from the graph calculating the difference between the pressure inside and outside the reservoir.

Your request was sent and will be answered as fast as possible.