M.2000-LD-RGB-F5

M.2000-LD

Handles with LED indicator light

78711-R,20

78710-R,10

78712-R,50

orGN 300-30-B5-SW;60

GN 612-5-M12x1,5-A;40

DIN 172-B10,5-20-A;50

ISO 8675-M8x1-04-BT;10

Type RGB, supply voltage 24Vdc +/- 10% (Max. current consumption = 120 mA). Colour tones may vary slightly depending on supply voltage.

Brass bushings, M6 threaded blind holes for rear mounting.

8-pole cable UL: AWG22 RAL9005 PVC UL AWM Style 1569/2517, back output, cable bending radius > 70 mm

IP67 and IP69K protection class, see Table EN 60529.

| Mechanical features | Electrical features | |||||

|---|---|---|---|---|---|---|

| Type of contacts: Ag 999 | Thermic power lth | Cable 4 A | ||||

| Connector 2.5 A | ||||||

| Insulation nominal UI voltage | Cable: 250 Vac | |||||

| Maximum operating frequency: 3600 cycles/hour * | Connector: 30 Vac/Vdc | |||||

| Short circuit protection: 4A 500V gG | Resistance between contacts: 25 mΩ | |||||

| Mechanical life-span: 10 million * | Category of use (cable) | |||||

| le/AC-15 ** | 24V-50/60 Hz | 4A | ||||

| 240V-50/60 Hz | 3A | |||||

| le/DC-13 * | 24V-d.c. | 2A | ||||

| 240V-d.c. | 0.4A | |||||

| Key action force: 30N | Category of use (connector) | |||||

| Cable bending radius > 70 mm | le/DC-13 (according to IEC 60947-5-1) | 24V-d.c. | 2A | |||

| B10D: 20 million manoeuvres | Pollution degree: 3 | |||||

* according to standard EN 60947-5-1

** according to standard EN 60945-5-1

| Electrical Utilisation Categories according to UL508 | M.2000-F (cable) | M.2000-C (connector) |

| AC control | 120Vac-3A | 24Vdc/2A |

| DC control | 24Vdc-2A |

The M.2000-LD handle is an ideal combination of ergonomics, functionality, and compactness.

In addition to the handle function, it integrates in a single product the function of signalling light column. These handles are typically assembled on machine doors or protections. With the appropriate electrical connection, it is possible to configure the colour of the LED strip to indicate the status of the guard (IEC 60204-1).

Example:

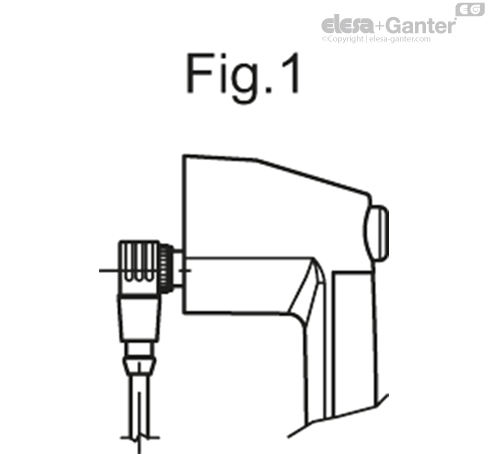

In case of use of an extension with angled connector, the direction of the cable output is shown in Fig.1.

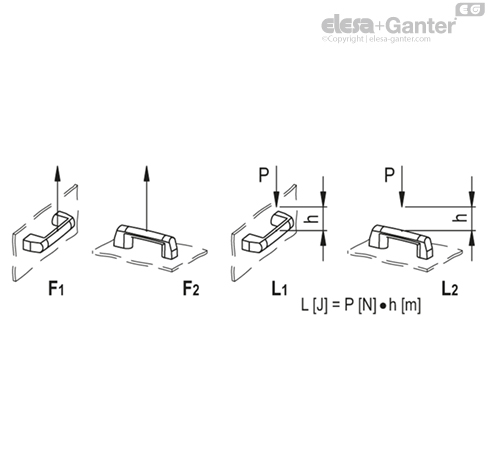

Tensile stress and impact strength: the values F1, F2, L1 and L2 indicated in the table were obtained during breaking tests carried out under the test conditions shown in the figure with ambient temperature.

The object of the above declaration described above is in conformity with the relevant European Union harmonisation legislation:

Harmonised standards and references to other technical specifications used in relation to which conformity is declared: EN 60947-5-1:2017

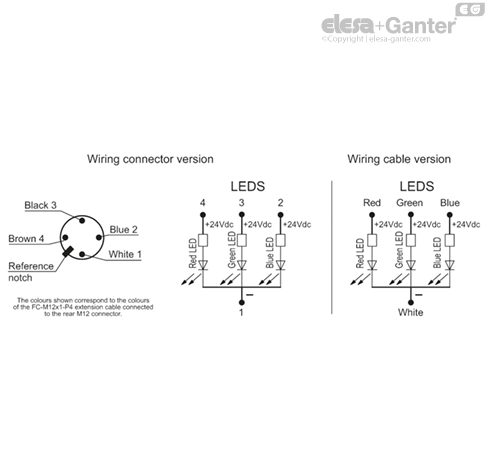

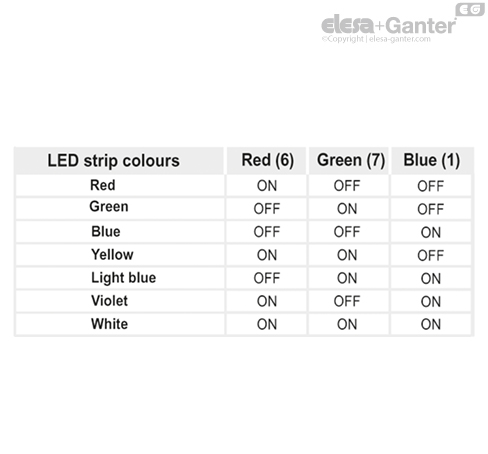

With appropriate cabling, it is possible to obtain one of the 7 colours of the LED strip.

The common contact (1) corresponding to the white wire (cable version) must always be connected to the negative pole of the power supply. The other three wires can be connected individually to the positive pole to respectively obtain the red, green, and blue colour of the LED strip, or connected simultaneously to obtain the remaining colours, as indicated in the table below. Other colours are possible by controlling the brightness of the individual channels with the PWM technique.

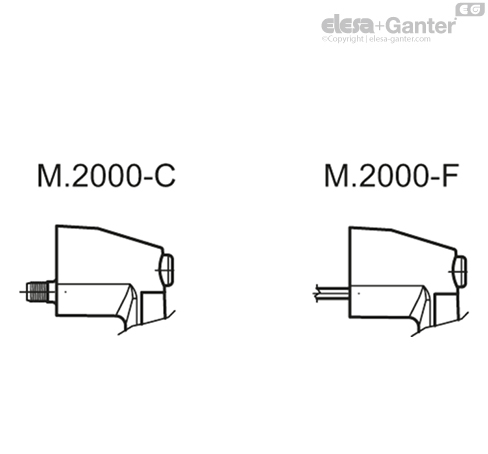

M.2000: Single complementary handle without switch.

M.2000-SWM: Handles with double contact monostable switch.

M.2000-SWM-LD: Handles with monostable switch and LED indicator light.

Your request was sent and will be answered as fast as possible.