GN 119.3-VK8

GN 119.3

Latches with Cabinet U-Handle

78711-R,20

78710-R,10

78712-R,50

orGN 300-30-B5-SW;60

GN 612-5-M12x1,5-A;40

DIN 172-B10,5-20-A;50

ISO 8675-M8x1-04-BT;10

Zinc die casting

Powder coated

Sheet Steel zinc plated, blue passivated

Steel zinc plated, blue passivated

Aluminum

Steel zinc plated, blue passivated

Latches with cabinet U-handle GN 119.3 are used when the application requires both a locking mechanism and a handle. They lock by a turning operation clockwise (right), which moves the cam latch into the locked position behind the door frame. The latches have a pulling-in range of 10 mm so that they can also be used together with seals, for example.

The various operating bolts and distance pieces allow for a clamping range A1...A9 from 17 to 65 mm.

The cabinet U-handle with integrated cam latch is a very attractively designed and cost-effective solution.

By turning the latch clockwise (right) the stepped cam latch moves up behind the door frame and pulls the door in.

The large pulling-in range of the cam (10 mm) allows these locks to be used successfully on doors with sealing strips. When selecting clamping range A the thickness of the seal might have to be taken into consideration.

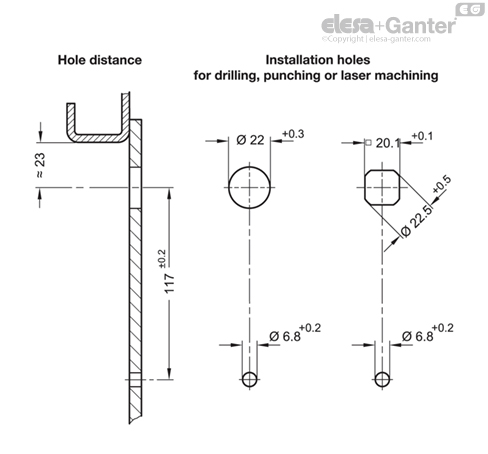

For installation, two holes must be made in the door according to one of the two outline drawings. The lock housing with the preassembled operating bolt is fitted into the hole from the front and held in position with the mounting nut on the back side. The distance piece and cam latch are then pushed one after the other onto the operating bolt from the back side and fastened with the hex head screw. The required installation holes in the door leaf, are usually generated by drilling, punching or laser machining in series production.

Your request was sent and will be answered as fast as possible.