Main specifications

Base

Zinc-plated steel.

Damping element

NR rubber, hardness 80 Shore A, black colour, matte finish.

Levelling plate

Zinc-plated steel.

Packing ring

NBR synthetic rubber O-Ring.

Threaded stem

Zinc-plated steel, supplied not assembled.

Nut and washer

Zinc-plated steel.

General information

Features

ELESA vibration-damping levelling elements have been designed to damp vibrations, shocks and noises produced by moving bodies or non-balanced vibrating masses of equipment and machines which can cause:

- malfunctioning and reduction of the machine lifespan and/or of the adjacent ones;

- damage to operator's health;

- noise.

Technical data and guidelines for the choice

- Basic data required:

- disturbing frequency: the frequency of the disturbing vibration produced by a on-duty machine. In general, it is obtained by the number of rotations of the engine [Hz=r.p.m./60];

- the load applied to every single vibration-damping element [N];

- the isolation degree required [%];

- the deflection value of the vibration-damping element under a given load [mm];

- the rigidity, that is to say the load that applied to the vibration-damping element produces a deflection of 1.0 mm [N/mm].

- How to choose the vibration-damping element:

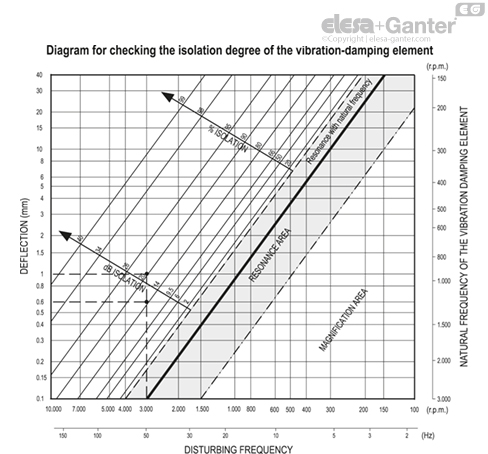

- with reference to the diagram for checking the isolation degree, intersect the disturbing frequency value with the isolation degree required (each isolation degree corresponds to a line in the diagram) and define the deflection [in mm];

- divide the load applied onto the vibration-damping element by the deflection value to obtain the required rigidity of the vibration-damping element;

- compare the rigidity obtained with the rigidity shown in the table and choose the vibration-damping element which presents the nearest value (lower) to the calculated one.

- Check:

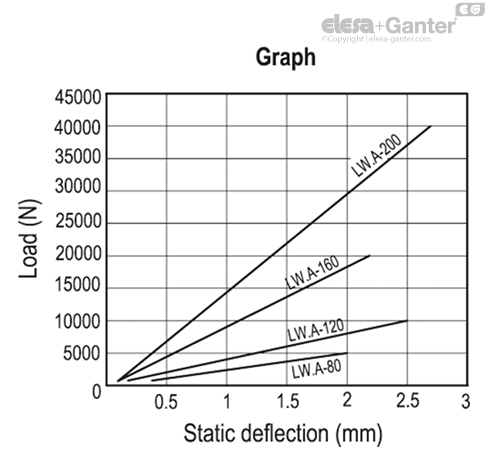

- the deflection of the vibration-damping element chosen can be obtained in the graph on the basis of the load;

- intersect the disturbing frequency value with the vibration-damping element deflection value in the diagram to obtain the isolation degree offered by the vibration-damping element chosen;

- compare the obtained value with the isolation degree required.

- Example:

- Conditions of use: disturbing frequency = 50 Hz (3,000 r.p.m.); load applied to every levelling element = 4,000 N; a 80% isolation degree is required;

- diagram shows that with a 50 Hz disturbing frequency and an isolation degree of 80%, the deflection obtained is 0.6 mm;

- divide the load applied by the deflection obtained to define the rigidity required, which is 4,000/0.6= 6,666 N/mm;

- compare the rigidity value obtained (6,666 N/mm) with the values reported in the table. This value is within the rigidity value reported in the table for LW.A-120 (4,000 N/mm) and LW.A-160 (9,000 N/mm). Choose the vibration-damping element with the lower value that is LW.A-120.

- graph shows that LW.A-120 (4,000 N/mm) deflection is 1mm.

- by intersecting the deflection value with the disturbing frequency of 50 Hz in the diagram, the isolation degree obtained is 90%.

This value is even greater than the required one; your choice has proved to be correct.