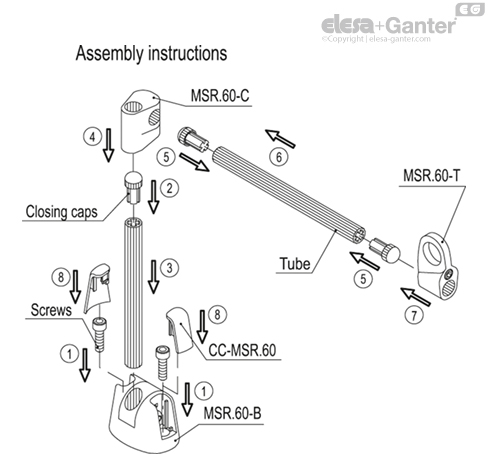

MSR.60-B

MSR.

Connecting clamps

78711-R,20

78710-R,10

78712-R,50

orGN 300-30-B5-SW;60

GN 612-5-M12x1,5-A;40

DIN 172-B10,5-20-A;50

ISO 8675-M8x1-04-BT;10

Available also as accessories sold separately (see table).

On request and for sufficient quantities other lengths are available.

Available also as accessory sold separately (see table).

MSR. connecting clamps, designed according to ELESA patent, allow an easy and efficient connection between the components, preventing the risk of rotating freely.

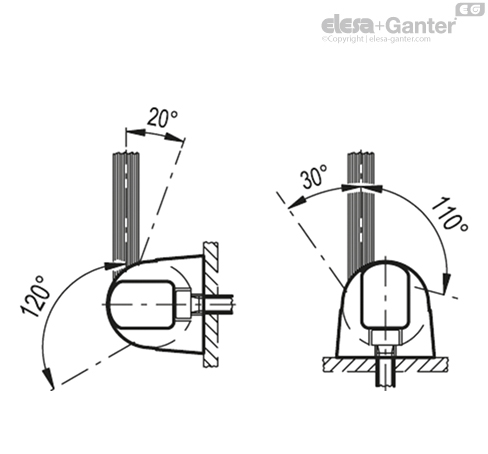

The system allows the axial, perpendicular or angled positioning of the connecting tube to the base.

The slot-shaped connecting tube preventing free rotation.

Tube and components clamped by the aid of only one screw.

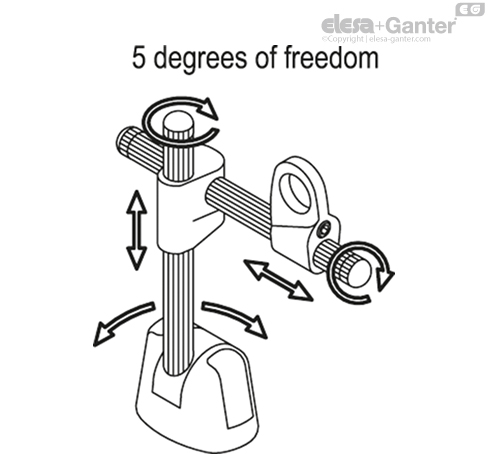

Easy adjustments by five degrees of freedom of the clamped devices (see drawing).

Lack of cavities to avoid the deposit of dirt and undesired substances.

Easy identification of the clamped device using different coloured caps on the base.

Your request was sent and will be answered as fast as possible.