GN 115-WOE-L-NI

GN 115-WOE-L

Latches

78711-R,20

78710-R,10

78712-R,50

orGN 300-30-B5-SW;60

GN 612-5-M12x1,5-A;40

DIN 172-B10,5-20-A;50

ISO 8675-M8x1-04-BT;10

Lock housing

Zinc die casting

Black, RAL 9005, textured finish SW

Operating elements

Plastic (Polyamide PA)

Black, matte finish

Zinc die casting

Powder coated

Black, RAL 9005, textured finish

Key

Nickel silver with plastic hand piece

Other parts

Steel, zinc plated, blue passivated

Protection class IP 65

Type SCK / SUK / SCT / SUT / LCG / LUG

Lock housing NI

Stainless steel AISI 303

Stainless steel AISI 316

Latch arm

Stainless steel AISI 304

Key

Nickel silver with plastic hand piece

Operating elements (Type SCKN, SCTN)

Stainless steel AISI 316

Other parts

Stainless steel AISI 304

Stainless steel AISI 316

Protection class IP 65 (Type SCKN, SCTN)

Lockable latches GN 115-WOE-L lock by a turning operation limited to 90° which moves the latch arm in the locked position behind the door frame. The bevels of the latch arm ease the closing of the door. Thanks to the stainless steel materials used, the latches are optimally suited for use in corrosive environments.

Latch arms are available with different bend angles to cover a latch arm distance A from 4 to 50 mm (version zinc die casting) and from 6 to 50 mm (version stainless steel).

The latches are delivered with 2 keys and loosely enclosed latch arm. The key can be removed in both end positions. The lock is standard, so that every lock can be opened with the same key.

Types with a standard lock allow every lock to be opened with the same key. For the types with different lock, there are more than 200 different lock variants, whose keys are marked by numbers.

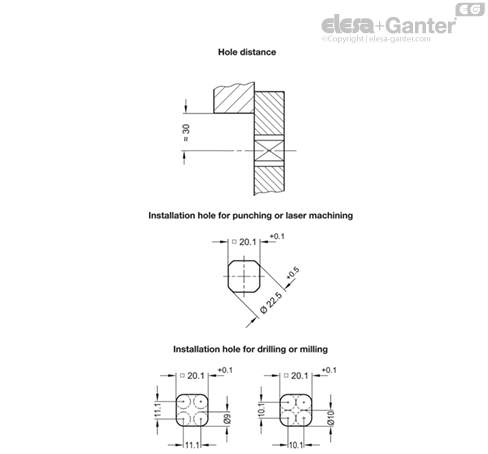

For installation, set a hole in the door, cover or hatch as shown in the outline drawing.

Once assembled, the latch is pushed through the bore diameter from the front. The hex nut can then be pushed over the latch from the back and bolted in place.

The required installation bore in the door leaf, is usually generated by punching or laser machining in series production.

The installation bore diameter can also be created by drilling or milling as shown in the outline drawings.

For small series and steel sheets below 2 mm thickness, the sheet metal punches GN 123 are the tool of choice.

Your request was sent and will be answered as fast as possible.